NIRMAL ENGINEERS

NIRMAL ENGINEERS

Home | Products | Schemes |

Services | Specialties of Nirmal |

News | Contact

Welcome your visit to this Nirmal page and thank you for your interest!

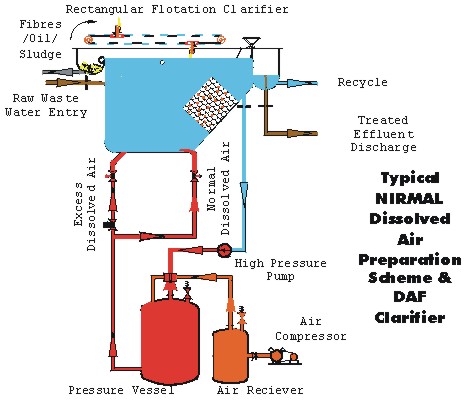

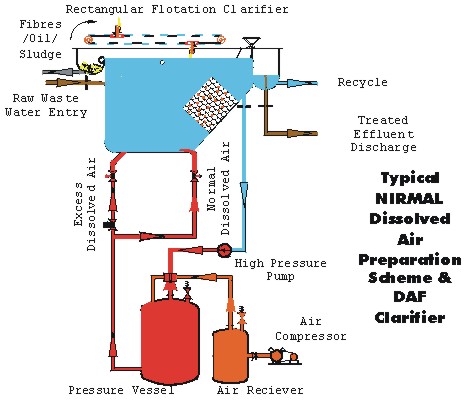

NIRMAL DISSOLVED AIR PREPARATION SCHEME

The dissolved air means mixture of air and water at a higher pressure. At higher pressures the

air can get dissolved and can remain in same state till the pressure is maintained. The air gets released

after the pressure is reduced. To dissolve the air, to maintain the dissolved state and to use for separation

process requires separate scheme. NIRMAL have specialized process in for this purpose.

Please

click here to see detailed view.

The treated effluent is used for dissolving air. The treated effluent is pumped by means of

multistage high pressure pump into high pressure motive stream side of water jet ejector. The specially

computer designed convergent nozzle forces the high pressure water into the high velocity jet which creates the

relative pressure drop and so low pressure zone on the suction side. Due to low pressure on the suction side,

the compressed air gets sucked and gets dissolved in the mixing zone of the water jet ejector. Since the

specific gravity of the air too smaller than water, more air gets sucked. The dissolution of air will be only

upto extent of saturation level. The extra air will remain undissolved. The mixture of air and water along

with excess additional air enters in the pressure vessel. The mixture of air and water will have air as

dissolved and so will have properties of water. This water is hence forth called as dissolved air, will move

vertically downwards. The excess air will move upwards which will get sucked automatically by the water jet

ejector. Thus air water ratio in the dissolved air will be maintained. In the pressure vessel due to the

retention time the size of the dissolved air is homogenized and uniform size air bubbles are available for

flotation.

The dissolved air will be inserted in the flotation clarifier through the throttled

dissolved air valves. The entry of the dissolved air will be from the bottom, so that entire portion of the

flotation clarifier will be stripped by the dissolved air and fine impurities will be made to float. The

throttled dissolved air valves will create the pressure drop as the flotation clarifier being open is at

atmospheric pressure. The throttled dissolved air will generate billions of microscopic ultra-fine air bubbles

which will adhere to the fats, oils, grease, fibres and suspended solids and make it to float upwards in the

form of compact sludge. The dissolved air will rise slowly maintaining the laminar state in the flotation

clarifier and will not disturb the flocculated state.

Overall the dissolved air bubbles will perform

following.

- The dissolved air bubbles act as nuclei for the attachment of

entire floating matter consisting of fats, oil grease, fibres, suspended solids and part of the colloidal

solids, and thus forcing the movement of the agglomerates of solids to the flotation clarifier surface.

- The dissolved air bubbles decreases the floc-solid + bubble density to less than that of water. More

the volume of bubbles attached to the solids will make the floc-solid + bubble the lighter in the density and

make the rise rate of the floc-solid + bubble floc on the higher side.

- The dissolved air bubbles will increase the oxygen level in the treated water

- It will also release dissolved gases out of

water.

The treated effluent will then pass through parallel plate coalescer to remove the air bubbles

from outgoing effluent. Such removal will polish the waste water not only for air bubbles but also for fine

impurities. This Mechanical Desludging, Hydraulic Desludging and Combined Desludging.

The multistage

high pressure pump capacity may not be same as actual dissolved air inserted in the clarifier. It is normal

convention to use higher capacity pump so that adequate dissolved air is ready for achieving the desired

results. For tuning the pump capacity and the actual dissolved air discharge, there are two methods employed.

- Make the multistage high pressure pump OFF after achieving the higher water level in the

pressure vessel. Since the entry of the dissolved air in the pressure vessel is stopped and the discharge is

occurring, the water level in the pressure vessel will be reduced upto lower most level. After achieving lower

level the multistage high pressure pump will be started automatically. The disadvantage is that pressure in the

pressure vessel will be reduced during OFF period of pump which will create dissolved air in the pressure

vessel. The size of air bubbles also will be increased making difference in flotation and so final results.

However this scheme requires simple control circuit. It could be easily employed incase the dissolved air as

well as the multistage pump capacity are low and the air compressor have relatively higher capacity, so the

pressure could be maintained in the pressure vessel. NIRMAL is using this method for initial 30 minutes after

starting the plant as the original pressure is zero.

- Keep the multistage high pressure ON regardless of water level in the pressure vessel. To reduce the water

level after achieving the higher level, the pneumatic actuated control valve gets opened automatically. Due to

additional opening of extra valve, more dissolved air is discharged to the flotation clarifier. The control

valve will remain open till lower most water level in the pressure vessel is achieved. This method requires

advanced control circuit and it will have dissolved air at a fairly constant pressure

It is also

important to maintain constant pressure. Only NIRMAL scheme uses following controls to maintain so as to

pressure variation less than 0.01 kg/cm2.

- The level control in the pressure vessel within maximum and minimum limits created constant

pressure head on the pump. Pressure drop of dissolved air in the pressure vessel to the tune of 0.1 kg/cm

2 will make the level rise by 1 meter which may reduce the free air content in the dissolved air and

thus may make the water to get sucked instead of free air. The low level in the pressure vessel may create

large air bubbles in the clarifier due to excessive escape of free undissolved air.

- The water level control in the pressure vessel is achieved by throttling the dissolved air valves so that

level variation is in control. The higher level in the pressure vessel will make pneumatic actuated control

valve open and discharge the additional extra dissolved air which will reduce the level in the pressure vessel.

The lower water level in the pressure vessel will make the control valve closed. The rise and fall in the

level could be seen visually in level gage and optionally could be checked by the flowmeter with alarms for

higher values. The throttling valves are specially designed to have protractor fixed to measure the rotation

and thus correct throttling could be achieved.

- In addition, the pressure in the pressure vessel is maintained between lower limits and higher limits. The

Higher pressure limit will make the extra pneumatic actuated control valve additionally ON or OFF during rise

of the water level in the pressure vessel. Lower pressure limit will make the air entry from the air receiver

ON or OFF. It will also make the extra pneumatic actuated control valve additionally OFF or ON during fall of

the water level in the pressure vessel.

- The air entry to the water jet ejector/pressure vessel is adjusted by measuring the actual flow in the

flowmeter and kept slightly above the bare minimum value.

- The treated effluent is filtered

through fine cartridge filters so that particles upto 25 microns or less if ordered. The filtering will make

the dissolved air valves less clogged and will deliver the constant dissolved air to the flotation clarifier.

The control circuit will be designed to have the operations automatic with additional safety measures.

Optionally alarm anunciators will indicate the measures to be taken to avoid worst conditions.

This site is under preparation.

Sorry for the inconvenience.

Last modified: March 13, 2004

Nirmal Engineers

17 Nav Sarvodaya Society, Vartak Road, Vile Parle (East)

Mumbai 400057, Maharashtra • INDIA

Phone / Fax: 91 22 26145623 • E-mail:

nirmal_daf@hotmail.com

Back to Top | Back to earlier page

Home | Products |

Schemes | Services |

Specialties of Nirmal | News

| Contact

NIRMAL ENGINEERS

NIRMAL ENGINEERS

NIRMAL ENGINEERS

NIRMAL ENGINEERS